Bellows and Bellows assambly

General

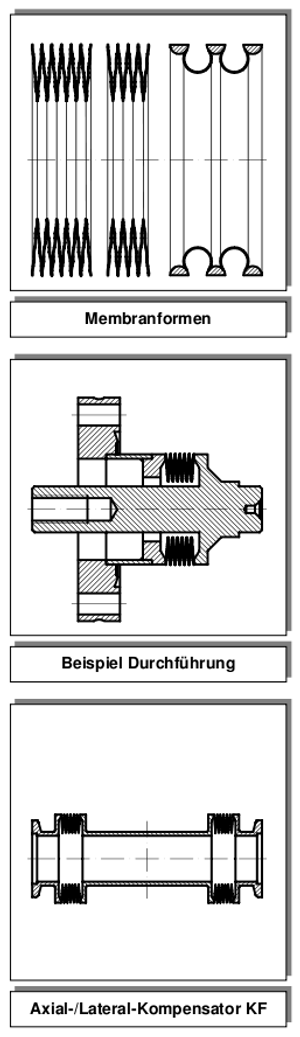

Edge-welded bellows are used in many special fields due to the versatile usefulness and the increasing thightness level in highly developed technologies. Edge-welded bellows achieve higher deformation than formed bellows. Furthermore, they offer large pressure strenght and show constant spring and working condition due to the high-grade shape accurency. Further advantages: no restriction of the producible bellows length and bellows form, Applicable for axial -, lateral and angular movement (or their combination) in vacuum -, ultra high vacuum or pressure range.

Applications

- Flexible connecting in piping systems

- Compensators for absorbtion of volume variations in closed recipients

- Valve shaft feed-throughs

- Flexible sealing element to rotary shaft seals, axial face seals

Design parameters

- Dimensions from 6 mm ID to approx. 1000 mm ID

- Shaped bellows (oval, rectangular) are realizable

- Temperatures from -272°C to approx. 750°C

- Life time depend on the design criteria, full cycles from nominal 10'000 to 10.000'000 possible

Materials

The most important criteria for choice of materials are:

- Mechanical behavior

- Sealing ability

- Chemical and thermal stability

- Radiation-proofness

- Stainless steel: AISI 304, 316, 316L, 321, 347

- Hardenable stainless steel: AISI 633, 17-4 ph., 17-7 ph .

- Nickel and nickel alloys (nickel, Monel, k-Monel, Inconel, Inconel X, Nimonic 75, Nimonic 90)

- Titan, Hastelloy B, Hastelloy C-276

End pieces / Flanges

IPractically, bellows assamblies are mnufactured inclusive standardized flange (KF, ISO-K, CF) or customized end pieces. All bellows assamblies are helium leak checked. Material certificates and leak check reports can be provided on request.

Construction Calculation

We support you during the design of bellows assambly and offer complete data sheets to you as a service.